Heat Transfer Paper vs. Sublimation Printing

So, you’re entering the wonderful world of T-shirt making and personalized garments—that’s exciting! You may be asking yourself which garment decoration method is better: heat transfer paper or sublimation printing? The answer is that both are great! However, the method you go with depends on your needs and what you’re looking to do. Plus, each method has its own advantages and disadvantages. Let’s dig into the details to help you decide which is the right fit for you and your business.

The Basics of Heat Transfer Paper

So, what is heat transfer paper exactly? Heat transfer paper is a specialty paper that transfers printed designs to shirts and other garments when heat is applied. The process involves printing a design onto a sheet of heat transfer paper using an inkjet or laser printer. Then, you place the printed sheet on your T-shirt and press it using a heat press (in certain cases, a home iron will work, but heat presses provide the best results). After you’ve pressed it, you peel away the paper, and your image adheres nicely onto the fabric. Great – you now have a custom T-shirt! That was easy, right? Garment decoration via heat transfer paper is super easy and carries one of, if not the lowest, start-up costs in the industry. In fact, many decorators get their start using nothing more than the printer they already have at home! A few other important notes about heat transfer paper is that most papers work on both cotton and polyester fabrics - while you’ll learn that sublimation only works on polyesters. In addition, heat transfer papers are designed to work for either dark or light-colored garments while sublimation is exclusively for white or light-colored garments.

Garment decoration via heat transfer paper is super easy and carries one of, if not the lowest, start-up costs in the industry. In fact, many decorators get their start using nothing more than the printer they already have at home! A few other important notes about heat transfer paper is that most papers work on both cotton and polyester fabrics - while you’ll learn that sublimation only works on polyesters. In addition, heat transfer papers are designed to work for either dark or light-colored garments while sublimation is exclusively for white or light-colored garments.

Ok, How About Sublimation

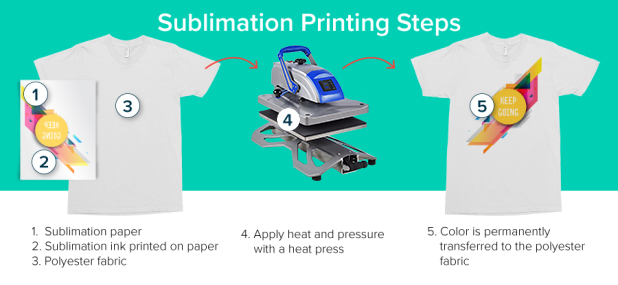

The sublimation process is quite similar to that of heat transfer paper. Like heat transfer paper, the process involves printing a design onto a sheet of specialty paper—sublimation paper in this case—and pressing it to a garment with a heat press. The difference lies in the science behind sublimation. Ready to get science-y?

Sublimation ink, when heated, turns from a solid to a gas that embeds itself into the polyester fabric. When it cools, it goes back to a solid and becomes a permanent part of the fabric. This means that your transferred design adds no additional layer on top, so there’s no difference in feeling between the printed image and the rest of the fabric. This also means that the transfer is incredibly durable, and under normal conditions, the images you produce will last as long as the product itself.

Sublimation ink, when heated, turns from a solid to a gas that embeds itself into the polyester fabric. When it cools, it goes back to a solid and becomes a permanent part of the fabric. This means that your transferred design adds no additional layer on top, so there’s no difference in feeling between the printed image and the rest of the fabric. This also means that the transfer is incredibly durable, and under normal conditions, the images you produce will last as long as the product itself.

Bonus! Sublimation not only works on polyester fabrics – it also works on a wide variety of hard surfaces with a poly-coating. This opens up an entirely new world of items you can customize - coasters, jewelry, mugs, puzzles and much more. Above two types of garment decoration method are what I would like to introduce to the beginners. Of course you can also Learn more to meet your different or larger demand by searching our website, www.xheatpress.com. If you’re interested in what I talked above and would like further information, our group will be ready and glad to offer you help.Our Email is sales@xheatpress.com and the official number is 0591-83952222.

Above two types of garment decoration method are what I would like to introduce to the beginners. Of course you can also Learn more to meet your different or larger demand by searching our website, www.xheatpress.com. If you’re interested in what I talked above and would like further information, our group will be ready and glad to offer you help.Our Email is sales@xheatpress.com and the official number is 0591-83952222.